Weld-On Hinges

Quick Overview

A weld-on hinge is mounted with a weld instead of fasteners, making it extremely strong and able to support a lot of weight. These hinges are useful on thick metal surfaces where it may be impractical to drill and tap holes, and they offer better alignment, while preventing give from side to side.

Many of our hinges are designed with an extended weld guide, which helps to align the rounded hinge on a flat surface—normally a tricky operation. Once the part is aligned, the hinge can be welded in place just like a standard barrel hinge.

Some hinges come with welded-on brackets or “open wings,” to make mounting and operation in different configurations practical and more efficient. We also offer a three-piece hinge for supporting extremely heavy loads. Some of our weld-on hinges come with a built-in grease fitting for easy lubrication, in order to prevent corrosion, increase part life and allow smoother operation.

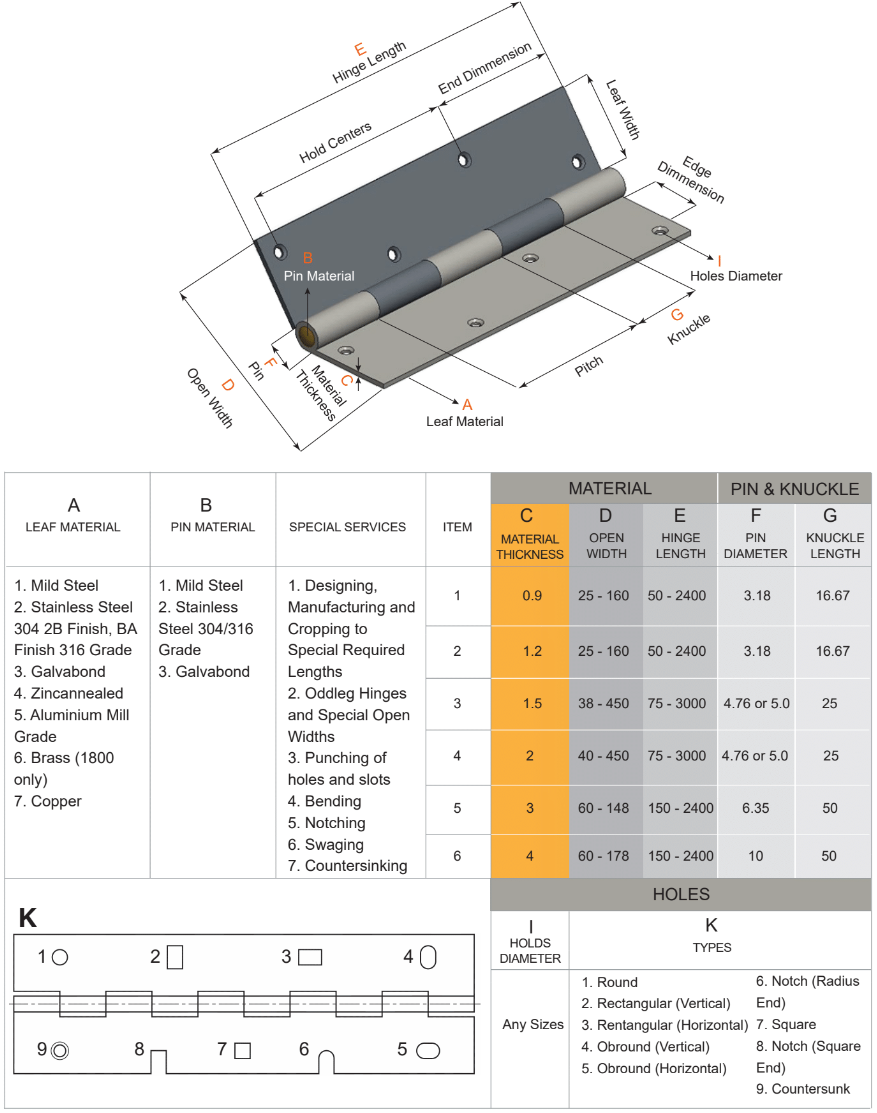

We manufacture weld-on hinges in aluminum, stainless steel and steel in a variety of sizes and finishes, and with bushings made of brass or stainless steel. Our hinge pins come in aluminum, brass, stainless steel or steel, in both fixed and removable pin styles. Removable pin weld-on hinges can be used as “lift-off” hinges for removable doors or gates.

GENERAL

The criteria in this guide is based upon yield load and not upon ultimate load (failure). The ratio of ultimate load to yield load is at least 1.5

for all hinges and is a natural safety factor. Impact or shock loads are not included. Additional safety factors should be considered based

on the material requirement. Generally harder materials, or metals, result in stronger hinges.

STRENGTH FACTORS

- Hinges are strongest in horizontal stress when the forces are applied perpendicular to the hinge pin.

- Hinges are weakest in vertical stress when the forces are applied parallel to the pin.

- In horizontal load, the strength per unit of length is constant. The longer the hinge, the stronger it will be.

- In vertical load, strength increases with the square of the length.

- As the hinge leaf thickness increases, hinge strength increases.

- As the diameter of the hinge pin is reduced, hinge strength increases provided the pin diameter is not reduced below twice the thickness of the leaf.

- Under vertical stress, shorter hinge knuckles provide greater strength.

RECOMMENDED SELECTION CRITERIA

- When applicable, use a hinge thickness approximately the same as the material to which the hinge is to be attached.

- Select hinges with the smallest possible knuckle length and having at least 10 knuckles.

- Choose a hinge having the smallest pin diameter (see 3.5) available for the hinge thickness selected.

- Apply a hinge with the knuckles always out if the hinge is to be used under horizontal stress only.

- Lubricating hinges weakens them by a factor of about 25%. Allow a safety factor of 25% if hinges are to be lubricated. Using this application, the strength will not vary with the angle of opening.

.png)