Lift-Off Hinges

Select Color

Quick Overview

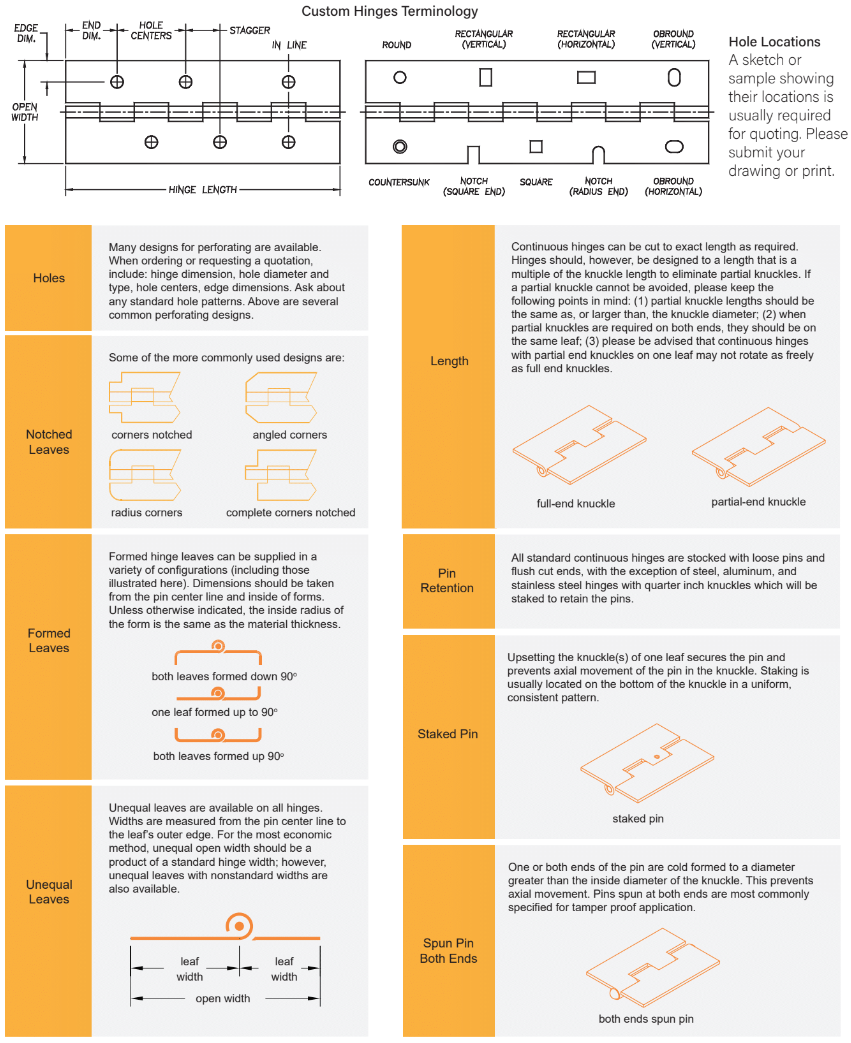

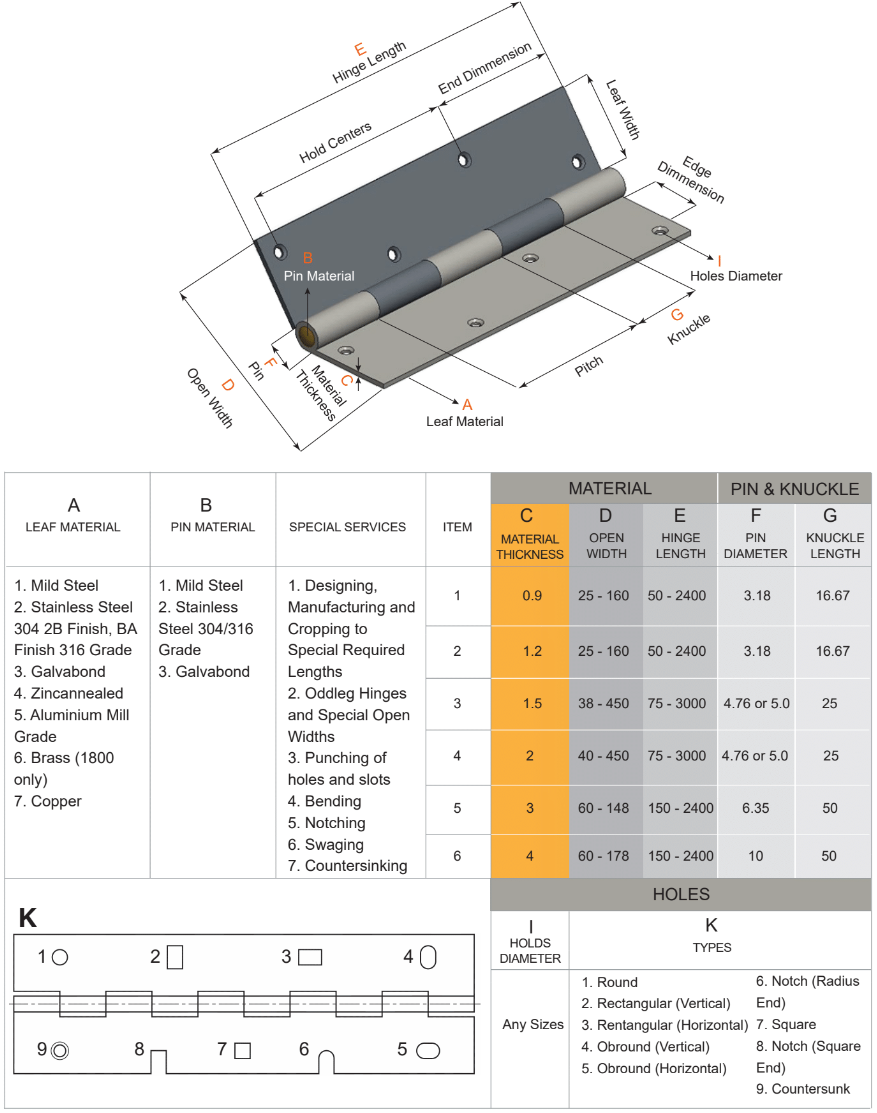

Our industrial quality lift-off hinges come in different styles, leaf widths, lengths, thicknesses, orientations and pin lengths to fit any application. Some lift-off hinges, called loose-joint hinges, are double wrapped, with a loose pin fitting into two separate, but identical, leaves. Others, called flag-joint hinges, come in male and female versions, with the male leaf assembly containing a staked pin, and the female leaf having a receptacle for the pin. These may be purchased separately or as a set.

A lift-off hinge can have a left-hand, right-hand, or reversible orientation, for use on doors that open either left or right. These come with or without drill holes (for mitered hinges).

GENERAL

The criteria in this guide is based upon yield load and not upon ultimate load (failure). The ratio of ultimate load to yield load is at least 1.5

for all hinges and is a natural safety factor. Impact or shock loads are not included. Additional safety factors should be considered based

on the material requirement. Generally harder materials, or metals, result in stronger hinges.

STRENGTH FACTORS

- Hinges are strongest in horizontal stress when the forces are applied perpendicular to the hinge pin.

- Hinges are weakest in vertical stress when the forces are applied parallel to the pin.

- In horizontal load, the strength per unit of length is constant. The longer the hinge, the stronger it will be.

- In vertical load, strength increases with the square of the length.

- As the hinge leaf thickness increases, hinge strength increases.

- As the diameter of the hinge pin is reduced, hinge strength increases provided the pin diameter is not reduced below twice the thickness of the leaf.

- Under vertical stress, shorter hinge knuckles provide greater strength.

RECOMMENDED SELECTION CRITERIA

- When applicable, use a hinge thickness approximately the same as the material to which the hinge is to be attached.

- Select hinges with the smallest possible knuckle length and having at least 10 knuckles.

- Choose a hinge having the smallest pin diameter (see 3.5) available for the hinge thickness selected.

- Apply a hinge with the knuckles always out if the hinge is to be used under horizontal stress only.

- Lubricating hinges weakens them by a factor of about 25%. Allow a safety factor of 25% if hinges are to be lubricated. Using this application, the strength will not vary with the angle of opening.

.png)